Click images below to view our work

What we offer

Corrocoat Hellas anti-corrosion technology provides a unique tool to combat the effects of harsh operating environments. The combination of high performance composites and mechanical engineering expertise gives us the upper hand in the fight against corrosion. Our coatings are available to protect your critical plant and structures from corrosion attack and help your bottom line through reduced repair, maintenance, replacement and downtime costs.

Using materials tailored to meet the demands of specific environments and problems, we offer comprehensive repair, protection and maintenance solutions, with the flexibility to respond swiftly and positively to individual client requirements providing a total package of corrosion prevention techniques to all forms of corrosion.

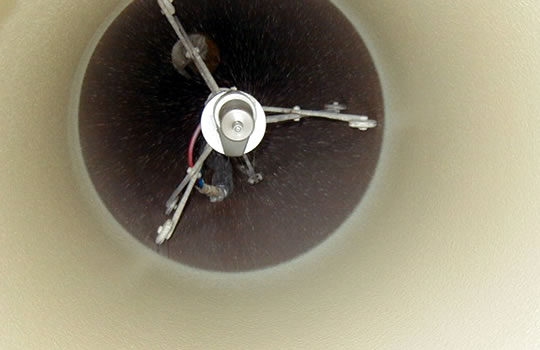

Corrocoat composites can be used to rebuild corroded and worn equipment to provide a repair that is strong and durable allowing severely damaged components to be refurbished and can be carried out at a fraction of the replacement cost. Corrocoat materials are extremely stable and can be machined to bring the component tolerances back to specification. When prevention is better than cure, coating new equipment can provide longer life and better performance.

Pumps, valves, pipes, heat exchangers, storage tanks, process vessels and many more all benefit from our expert treatment.

Corrocoat Hellas is geared up to offer the following services to our esteemed customers

- Study customer requirements and offer exact solution to give long-term corrosion protection.

- Supply of coating material with application back-up.

Execute in-house as well as on-site coating application work which includes:

- Decontamination of surface

- Surface Preparation – blast cleaning to ensure proper adhesion of coating

- Environmental checks – e.g. temperature, humidity etc.

- Coating application

- Coating inspection

- Engineering services when required