Advanced Glassflake Technology

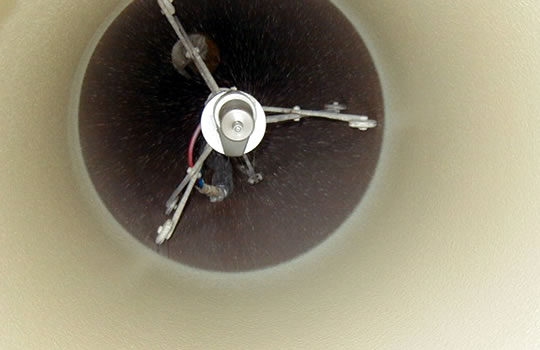

This development was pioneered entirely by Corrocoat UK’s own Research and Development team. Corrocoat coatings use glass flake fillers, which are impermeable and significantly increase the diffusion path through the coating. This produces a barrier layer, slowing moisture diffusion and the corrosion potential to an almost non existent level.

The flakes of glass orientate themselves within the coating film to reduce the passage of moisture vapour. This effect is known as the tortuous path. Corrocoat’s sister company produces the unique, uniform, and high aspect ratio glass flakes.

Substantial coating improvements are achieved by using these flakes rather than the variable and much thicker flakes or beads available in other coatings.

The end result is Corrocoat materials achieve better corrosion protection.

Benefits of glass flake technology:

- Excellent temperature resistance

- Excellent chemical resistance

- Excellent dry and immersed adhesion

- Low permeation rate

- Applicable over a wide range substrates

- High abrasion resistance

- Dimensional stability

- Impact resistance

- Repairability

- Machinability

- High tensile strength

- High resistance to cathodic disbondment

- Durability, very long service lives

- Very low Volatile organic compounds

- Cost effective